FAC System: historical overview

Fac, also known as FAC system was invented in 1952 by the Swedish artist Mark Sylwan. FAC is a modulair construction system, designed to develop mechanisms, machines and other prototypes in a rapid and easily understood 3D form. Nowadays parts can be ordered directly from the factory.

Around 1955, 3 years after it’s invention, FAC was introduced in Holland, specially on demand of Philips. The import was assigned to technical office Koppe from Wassenaar. There was a huge interest for Fac as from the beginning on no less than 35 companies or educational institutions bought FAC. These companies used FAC as a design tool for a variety of purposes. TNO Delft, the Technical Universities of Eindhoven and Delft and Philips all used FAC. FAC became a succes, but this can only be understood if we look at the social contect of that time.

Until WWII consumer products were manufactured mainly by hand. After WWII, living standards of an ever growing population did rise rapidly, which resulted in an increasing demand for consumer goods. Manual production within an industrial setting was no longer profitable.

The Production Mechanization (PM), an instrument to fullfill in a companies need of specific production capabilities within an industrial setting, focussed on mass fabrication is as old as the company itself. For example the PM Light originated during the invention and production of the lightbulb back in 1891, the year Philips was established. After WWII however, the PM developed itself enormously related to the needs of new consumer products like razors, radios, kitchenequipment etc.

Instead of manually manufactured goods, machines took over the work. These machines had to be desigend first and the designing process itself is an intriguing process.

The development of prototype machines was partly done behind the drawingboard and partly by real prototyping with custommade parts. The materials used were often produced conform high engineering standards. This method of designing however was expensive and timeconsuming.

One of the ways to simplify this process was to use ready built parts to be used within a modulair system.

The purpose is to design and construct mechanisms and machines. If one has constructed and tested such a mechanism it either can work or not. If not, the mechanism must be modified until it meets it’s requirements. This proces can be done rapidly with a modulair system only.

Fac did meet to all these system requirements.

FAC uses axles which measurments are 4 and 6mm. Philips extended this range with 10, 15, 25, 40, 60mm etc. This range was developed and sold under the name Philips Variabel Bouw Systeem via the Philips Machine fabriek in Alkmaar.

Philips and FAC

Philips was a keyplayer related to the PM. The method of orthocyclic coil winding was one of the many subjects in the early 50’s of the 20th century this company was involved with.

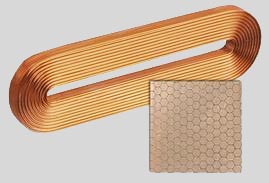

Orthocyclic winding is a method for obtaining coils whose turns are stacked in the most compact fashion possible. Such coils have certain particularly good properties including good heat conduction, even distribution of electric field strenghts and the highest possible space factor.

orthocyclic coil and a principle fragment of a section

orthocyclic coil and a principle fragment of a section

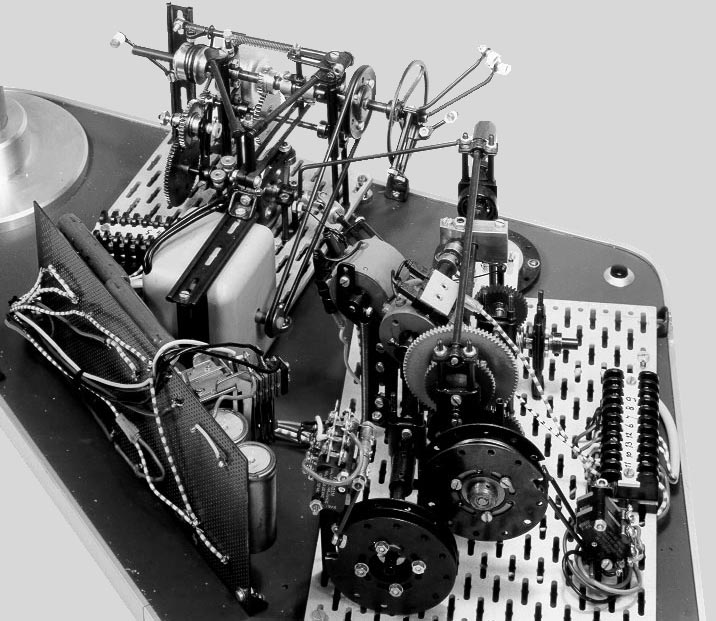

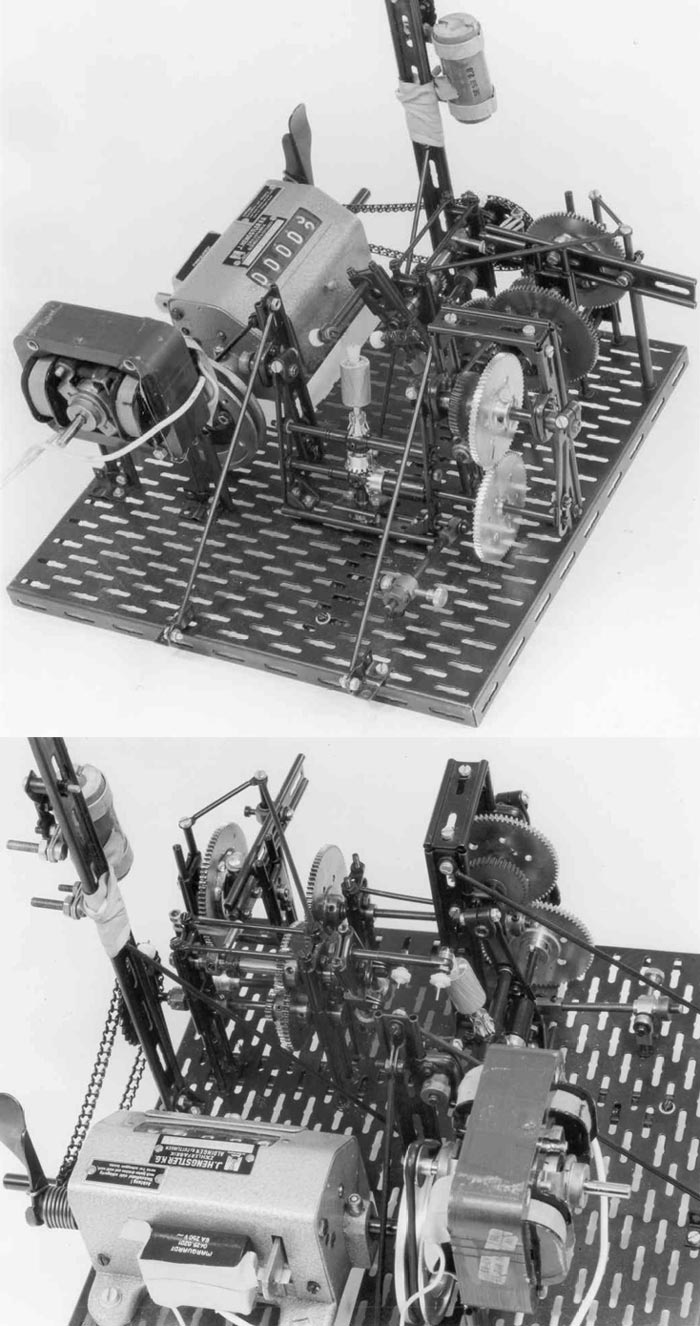

Positioning of several machine components and their interaction related to orthocyclic winding is essential. These components are responsable for putting the copperwire on it’s correct place. The pictures below show two different prototypes of an variant of an orthocyclic coil winding machine assembled with FAC parts around the mid 1960’s. Only a few parts are custom made like the nylon pulleys on the topend of each guideaxle of the steering wheel.

prototype 1, flyerwinding machine for hollow rotorcoils (photo with courtesy of fam. van Hirtum)

prototype 1, flyerwinding machine for hollow rotorcoils (photo with courtesy of fam. van Hirtum)

prototype 2, flyerwinding machine for hollow rotorcoils (photo with courtesy of fam. Lenders)

prototype 2, flyerwinding machine for hollow rotorcoils (photo with courtesy of fam. Lenders)

The engineers involved with orthocyclic winding and the winding machine were ing. W.L.L. lenders (1923 - 1998) and ing. M.J. van Hirtum (1937 - 2006).

The prototypes as shown above were meant to be developed to a new model, capable of producing orthocyclic coils in high numbers. Prototype 2 however, was such a succesfull model, that Philips decided to produce 5 of these. By 1967, they all were installed in the Philips factory “Johan de Wit” in Gorkum (near Rotterdam). Every machine produced 1 coil a minute.

The coil winding machines worked for about 18 months. By an increasingly demand a new generation of coil winding machines had to be produced capable of producing coils in higher numbers in a shorter time. The 5 Fac coil winding machines didn’t meet with these requirements and therefore, by 1969 they were of no use anymore in the PM and around this time they all were thrown away!

FAC in the 70’s until present time

From the 70’s on practice changed from the visible fine mechanical engineering to mechatronics and mircrotechnology (to nanotechnology anno 2006). The development of the microchip and large scale use of computers from the mid 80’s indicate a new way of developing machines and prototypes on behalf of the PM.

I know from my own experience (architecture), that the use of the computer is inevitable and speeds up the designproces.

However, by making fysical prototypes or 3D models one can actually see and feel it’s working. A computermodel is more abstract and limited in it’s imagination.

The art of designing is to find a balance in the advantages a computerdesign can give and by using 3D rapid modelling tools. Fac is such a design tool.

FAC is alive!!

Parts of the text were taken from:

- vakantieleergang werktuig- en scheepsbouw 1964 - prof. ir. W. van der Hoek

- The orthocyclic method of coil winding - ing. W.L.L. Lenders, Philips Technical Review nr. 12, 1961/62)